Air Separation Technology

An air separation plant separates atmospheric air into its primary components, typically nitrogen and oxygen, and sometimes also argon and other rare inert gases.The most common method for air separation is cryogenic distillation. Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon. Other methods such as membrane, pressure swing adsorption (PSA) and vacuum pressure swing adsorption (VPSA), are commercially used to separate a single component from ordinary air.

An air separation plant separates atmospheric air into its primary components, typically nitrogen and oxygen, and sometimes also argon and other rare inert gases.The most common method for air separation is cryogenic distillation. Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon. Other methods such as membrane, pressure swing adsorption (PSA) and vacuum pressure swing adsorption (VPSA), are commercially used to separate a single component from ordinary air.

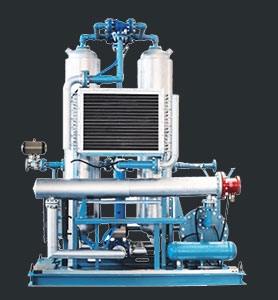

PRESSURE SWING ADSORPTION (PSA):

PSA provides separation of oxygen or nitrogen from air without liquefaction. The process operates around ambient temperature; a zeolite (molecular sponge) is exposed to high pressure air, then the air is released and an adsorbed film of the desired gas is released. The size of compressor is much reduced over a liquefaction plant, and portable oxygen concentrators are made in this manner to provide oxygen-enriched air for medical purposes. Vacuum swing adsorption is a similar process, but the product gas is evolved from the zeolite at sub-atmospheric pressure.

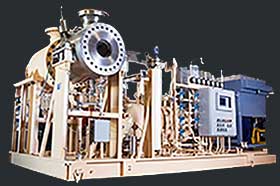

MEMBRANE SYSTEM

can provide alternate, lower-energy approaches to air separation. For example, a number of approaches are being explored for oxygen generation. Polymeric membranes operating at ambient or warm temperatures, for example, may be able to produce oxygen-enriched air (25-50% oxygen). Ceramic membranes can provide high-purity oxygen (90% or more) but require higher temperatures (800-900 deg C) to operate. These ceramic membranes include Ion Transport Membranes (ITM) and Oxygen Transport Membranes (OTM). Air Products and Chemicals Inc. and Praxair are developing flat ITM and tubular OTM systems, respectively.

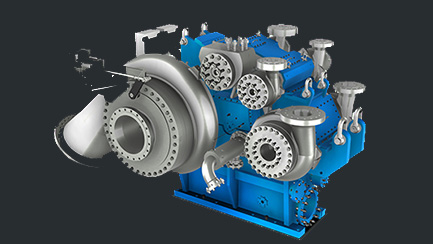

CRYOGENIC AIR SEPARATION PLANT

Plants Advantages & Specification include:

- Reliable design of equipment and Robust plant and component

- Long-lasting relationships with well-known and highly reliable best-in-class suppliers, especially for rotating equipment

- Advanced process control for continuous optimization of plant production in line with customer requirements Easy and low maintenance and smooth operation

- Low CAPEX/OPEX through advanced & optimized process design

- Reliable design of equipment and Robust plant and component

- Long-lasting relationships with well-known and highly reliable best-in-class suppliers, especially for rotating equipment

- Advanced process control for continuous optimization of plant production in line with customer requirements Easy and low maintenance and smooth operation

- Low CAPEX/OPEX through advanced & optimized process design

- Outstanding design and build quality of core components and certified in line with international standard such as ISO 9001 (quality management)

- Comprehensive, proven control and redundancy philosophy to ensure continuous production

- Prominent reference plants including the world’s largest units and multiple train solutions

- On time and quality after sale service around the country

We comply with the highest safety, health, environment and quality (SHEQ) standards and codes to deliver air separation plants offering outstanding efficiency, superior plant availability and lowest operation costs.

Catalogue