Reciprocating Air Compressor

Reciprocating piston compressors, sometimes called just piston compressors, were some of the first machines invented to compressed air. Their design is constantly being refined as technology and materials improve, and they’re widely used still to this day. Many industries rely on reciprocating compressors for their compressed air needs.

Reciprocating piston compressors, sometimes called just piston compressors, were some of the first machines invented to compressed air. Their design is constantly being refined as technology and materials improve, and they’re widely used still to this day. Many industries rely on reciprocating compressors for their compressed air needs.

Reciprocating piston compressors, sometimes called just piston compressors, were some of the first machines invented to compressed air. Their design is constantly being refined as technology and materials improve, and they’re widely used still to this day. Many industries rely on These compressors for their compressed air needs.

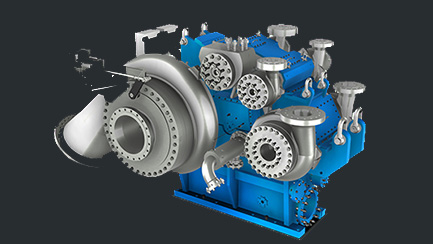

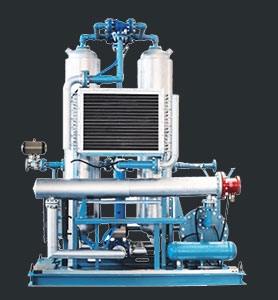

Of the most popular air compressors technologies available, the most economical and relatively inexpensive type of air compressor is the piston or reciprocating machine. Nothing could be further away from this reality than the contribution today’s modern These compressors technology is making to industrial productivity. The majority of small-to-medium piston compressors, which commonly range from 0.55 to 15 kW and can be either oil-lubricated or oil-free machines, are available in a number of product variants to match the exact needs of a wide range of end users.

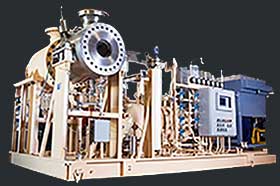

These compressors are becoming a critical part of many processes and the need for machines is growing year on year. You can find them being used in Refineries, Refrigeration, Oil & Gas, Chemical Manufacturing, Automotive, Agriculture, Medical Surgery etc.

These compressors work on the principle of reciprocation, which means to move something back and forth. They are positive displacement type compressors meaning when the air is mechanically reduced, a corresponding increase in pressure occurs. These compressors use pistons to compress air.

What is a reciprocating air compressor used for?

For small-scale compressed air applications (below 15 KW), Havayar offers reciprocating air compressors that provide a powerful combination of reliability, flexibility, and low operating costs. Depending on the requirements, the compressor can be offered in an oil-free or lubricated version. It is designed with a compact installation and a limited number of working parts to ensure performance in harsh conditions and facilitate simple maintenance.

Also, for higher pressures up to 350 barg or air boosters, These compressors are the best choice in terms of maximum efficiency. Havayar can provide optimal customer service from the initial inquiry and throughout the product’s lifespan.

Reciprocating Air Compressor Benefits

Some of the critical benefits of a reciprocating air compressor are:

- High pressure and power: These compressors can push out high pressure and energy, even though they are compact.

- Low maintenance costs: These compressors have fewer moving parts than others, which leads to less wear and tear and part replacement.

- Improved efficiency: These compressors can be used intermittently and do not need to run continuously. They produce high power at low energy levels and can help lower your outputs. They are best used when turned on and off frequently.

- Longer product life: As these compressors do not run repeatedly, they are less likely to need repairs. You can get more time out of your compressor.

- Compact design: These compressors are smaller than other styles, making them easy to transport and place closer to the work site. If you work in oil and gas, a portable compressor can help on multiple sites.

Frequently Asked Questions

For small-scale compressed air applications (below 15 KW), Havayar offers reciprocating air compressors that provide a powerful combination of reliability, flexibility, and low operating costs. Depending on the requirements, the compressor can be offered in an oil-free or lubricated version. It is designed with a compact installation and a limited number of working parts to ensure performance in harsh conditions and facilitate simple maintenance. Also, for higher pressures up to 350 barg or air boosters, reciprocating air compressors are the best choice in terms of maximum efficiency. Havayar can provide optimal customer service from the initial inquiry and throughout the product’s lifespan.

Some of the critical benefits of a reciprocating air compressor are: High pressure and power, Low maintenance costs, Improved efficiency, Longer product life, Compact design

Industrial reciprocating compressors are becoming a critical part of many processes and the need for machines is growing year on year. You can find them being used in Refineries, Refrigeration, Oil & Gas, Chemical Manufacturing, Automotive, Agriculture, Medical Surgery etc.

Reciprocating air compressors work on the principle of reciprocation, which means to move something back and forth. They are positive displacement type compressors meaning when the air is mechanically reduced, a corresponding increase in pressure occurs. Reciprocating compressors use pistons to compress air.

sales department

after sales service

datasheet

datasheet

catalogue